Linxuan Laser is a professional laser marking machine manufacturer, that can supply quality industrial laser marking machine at a competitive price. Linxuan Laser marking machines have stable performance and are easy to operate and maintain.

Support customization

Good aftermarket, Long guarantee period

Professional and timely after-sale service

Custom Laser Marking Machine Supplier

Linxuan Laser has rich experience in laser technology and a professional team. We have accumulated valuable knowledge and skills in the field of laser marking. We can design and customize various types of laser marking machines according to customer needs. Regardless of the industry and application scenario, choosing our customized laser marking system will provide you with superior equipment and professional services to help you realize your personalized needs and achieve greater success.

Laser Types of Linxuan Laser Marking Machine

Linxuan Laser develops and produces fiber laser marking machines with the newest laser technology. We have many models that can be matched freely to meet various demands on yielding and types of laser marking.

Linxuan Laser offers high-performance CO2 laser marking machines. They have stable and reliable performance, marking fast and precise. Our laser marking equipment is easy to operate and maintain.

Features of Linxuan Laser Marking Machine

Portable Laser Marking Machine

Our portable laser marking machine is small and lightweight, easy to carry and move, making marking operations more flexible and convenient. It is suitable for various occasions and environments, such as outdoor construction, exhibition sites or mobile maintenance, etc.

Desktop Laser Marking Machine

Linxuan desktop laser markers are manufactured using advanced technology and exquisite craftsmanship, ensuring stable performance. We provide a full range of after-sales services and technical support to ensure a satisfactory experience during purchase and use.

Flying Laser Marking Machine

Our flying laser marking machine is equipped with advanced control systems. Whether in industrial production lines or batch processing scenarios, choosing our flying online laser marker will bring you efficient and reliable marking solutions and help you achieve greater success.

Handheld Laser Marking Machine

Linxuan has been committed to producing high-quality, reliable and portable handheld laser marking machine. They not only excel in marking accuracy and speed, but also offer unparalleled comfort and flexibility in operation.

Whether you need to add personalized logos to small products or do marking work in a limited space, Linxuan mini laser marking machines can provide accurate and high-quality marking effects. Create unlimited possibilities for the home!

Linxuan Laser Marking Machines by Materials

Laser Marking Machine for Metal

Linxuan metal laser marking machine is versatile and suitable for various metal materials, such as stainless steel, aluminum, copper, gold, silver, alloy, etc. We ensure long-term stable operation of our equipment through strict quality control and continuous technology upgrades.

Laser Marking Machine for Plastic

We offer high-quality laser marking machine for plastic to provide customers with excellent plastic marking solutions. A variety of marking forms such as text, patterns, and QR codes can be realized to meet the needs of different industries and applications.

Laser Marking Machine for Wood

Whether you are in the furniture manufacturing, woodworking, or art decoration industry, choosing our company’s wood laser marking machine will bring you efficient and accurate marking solutions, helping you achieve greater production efficiency and creativity.

Laser Marking Machine for Leather

The equipment has stable and reliable performance, can complete marking tasks quickly and efficiently, and is suitable for various leather product production needs. The professional team is ready to solve problems to ensure that customers get the best experience and support.

Laser Marking Machine for Glass

We provide a full range of after-sales services, including training, maintenance, and technical support, allowing customers to use the equipment worry-free. Choosing Linxuan glass laser marking machine will be your wise decision.

Laser Marking Machine for Acrylic

Linxuan laser marking machine for acrylic combines precision, efficiency and reliability to bring more vitality to your production line. Whether it’s a delicate pattern or a complex logo, our equipment can handle the job with ease, giving you stunning results.

Guide to Buying a Laser Marking Machine for Beginners

As an important process in modern manufacturing, laser marking technology is increasingly receiving widespread attention and application. Laser marking machines show their unique charm and practicality in industrial production or personal creation. This guide is designed to provide comprehensive guidance to help you gradually understand the basic principles, operating techniques, applications of laser marking machines, and other knowledge.

How Does a Laser Marking Machine Work?

Laser Generation: Laser marking machines use lasers as light sources. Common types include fiber lasers, CO2 lasers, and UV lasers. These lasers produce high-energy, monochromatic laser beams through electrical excitation or gas discharge.

Beam Focusing: The laser beam is focused on a small area through a lens or lens system to form a high-density energy focus on the workbench.

Marking: The laser beam irradiates the material surface to be marked, causing the material surface to melt, vaporize, or reach the ignition point. At the same time, the molten material is ejected with the help of pressure difference, leaving a permanent mark on the material surface, such as text, pattern, QR code, etc.

Why Choose the Laser Marking System?

Non-contact Processing: The laser marking machine adopts non-contact processing. The laser beam is directly irradiated on the material surface without physical contact, avoiding problems that may cause wear, deformation, or contamination.

High Precision and Fineness: Laser markers have high precision and fineness, and can achieve small and clear patterns, text, or barcode markings. It can produce extremely fine lines or tiny structures on the surface of materials.

High-speed Processing: Laser marking machines are easy to operate, allowing for fast and efficient processing. It can perform continuous marking at a high speed and is suitable for mass production needs.

Wide Range of Applications: Laser markers are suitable for various materials, including metals (such as gold, silver, steel, aluminum, etc.), plastics, ceramics, glass, paper, and cloth. Almost any material that can interact with lasers can be marked.

High Durability: Laser-marked markings are highly durable and can withstand daily use, wear and tear, and environmental impacts. Markings are not susceptible to fading, abrasion, or chemical attack.

Flexibility: Laser marking machines can achieve different marking effects, such as text, numbers, patterns, trademarks, QR codes, barcodes, etc. Users can customize the design mark content according to their needs.

Environmentally Friendly: Laser marking is a pollution-free, waste-gas-free, and low-energy consumption processing method. Compared with traditional methods such as chemical etching and mechanical engraving, it has less environmental impact.

High Degree of Automation: It can realize automatic marking, automatic detection, automatic calibration and other functions, greatly improving production efficiency.

Multiple Marking Methods: The marking machine laser uses advanced control systems and software to achieve kinds of different marking needs, such as dynamic marking, static marking, positioning marking, etc.

What Are the Disadvantages of Laser Marking Machine?

Laser marking machine is widely used in various industries as efficient marking equipment. However, like all technological products, laser marking machines have some disadvantages.

High initial cost: As precision industrial equipment, laser marking machines have relatively high manufacturing costs and technical content, so their selling prices are also relatively high. This can put a financial strain on small businesses or individual users.

Safety risks: Laser marking machines use laser beams for processing. If used incorrectly or improperly operated, it may cause eye, skin, and other parts injuries. Therefore, safety operating procedures need to be strictly followed, and protective glasses and clothing should be equipped when necessary.

Material limitations: Some specific materials may not be suitable for laser marking, such as flammable items or some metallic materials, or the surface coating may be insensitive to laser or susceptible to damage, which may limit the application range.

Noise: The laser marking machine will produce a certain amount of noise and vibration during use.

Despite these shortcomings of laser marking machines, they can still be an efficient and accurate processing tool when used and managed correctly. Therefore, when choosing a laser marking machine, you should fully consider your needs and actual conditions and choose the right equipment.

Application of Laser Marking Machine

Laser machine for marking is widely used in many different application scenarios.

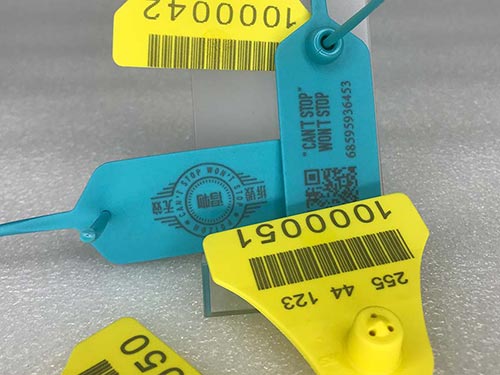

Industrial Manufacturing: Laser marking machines can mark and engrave serial numbers, date codes, barcodes or QR codes on products to achieve product traceability and anti-counterfeiting functions. They can also create permanent markings on metals, plastics, ceramics, and more.

Electronics: Laser marking machines can accurately mark electronic components such as integrated circuit chips, electronic devices, wires, and cables, etc., to help identify and track products.

Medical Devices: Surgical instruments, medical equipment, artificial joints, etc. This helps identify, track, and confirm product authenticity.

Automotive: Laser marking machines can mark auto parts, such as engine parts, tires, glass, etc. This helps track and manage parts, improving production efficiency and quality control.

Food and Beverage Packaging: Laser marking machines can mark food and beverage packaging for date, batch number, brand logo, etc. This helps ensure product traceability and quality safety.

Jewelry and Watch: Trademarks, style numbers, fine patterns, etc. can be marked on jewelry and watches. This adds a unique identity and value to the product.

How to Choose a Laser Marking Machine?

Marking Needs: First of all, you must clarify your own marking needs, including the type of materials that need to be marked, the size and complexity of the marked content, production efficiency requirements, etc. Different laser marking machines are suitable for different materials and application scenarios. It is important to choose the model that suits your needs.

Laser Types: Common laser types include fiber laser, CO2 laser, UV laser, and solid-state laser. Each laser has different characteristics such as power, wavelength, stability, and reliability. Choose the appropriate laser type according to your needs.

Power and Speed: The power of the laser marking machine determines its marking speed and depth. Higher power usually means faster marking speeds and deeper marking capabilities. Select the appropriate power level based on production efficiency and required marking depth.

Beam Quality: Beam quality directly affects the accuracy and clarity of marking. Good beam quality can achieve more detailed and clear marking effects. Examine samples and test markings provided by the manufacturer to evaluate beam quality.

Configuration Selection: The configuration selection of the laser marking machine mainly includes laser, galvanometer, field lens, marking card, industrial control computer, cabinet shell, ruler and lifting shaft, etc. Choose the appropriate configuration according to your needs to achieve the best marking effect and production efficiency.

Equipment Stability and Reliability: Choose a laser marking machine manufacturer with a good reputation to ensure the stability and reliability of the equipment. This will affect the long-term use and maintenance costs of the laser equipment.

After-sales Service and Support: Understand the manufacturer’s after-sales service and support policies, including warranty period, training and technical support, etc. Ensure timely technical support and maintenance services are available.

How Much Does a Laser Marking System Cost?

Laser marking machine price varies based on brand, model, features, power, and additional options. Generally speaking, the price range of a laser marking machine is around US$1,000 to hundreds of thousands of dollars.

Low-power (10w/20w/30w) mini, small, and portable laser marking machines are more affordable, generally ranging from $1,000 to $3,500.

A small desktop laser marking machine may cost around $2,000 to $5,000.

The price of a large industrial-grade laser marking machine may be tens of thousands of dollars or even higher.

Under the same conditions, the UV laser marking machine price is higher than the CO2/fiber laser marking machine price.

How Large Can a Pattern or Text Be Marked?

The size of the marked pattern or text is limited by the working area and focal length of the laser marking machine. The exact size range depends on the specifications and parameters of the selected laser equipment. Typically, laser marking machines are capable of achieving marking patterns or text ranging from minute details to larger sizes.

What is the Speed of Laser Marking?

The speed of laser marking depends on several factors, including the type of laser used, its power settings, the depth of the mark required, and the complexity of the pattern or text.

Are Laser Markings Permanent?

Marks produced by laser marking are usually permanent because they are achieved by causing chemical or physical changes on the surface of the material. This makes the markings extremely resistant to abrasion, corrosion, and weathering.

Does the Laser Marking Machines Require Maintenance?

Laser marking machines usually require regular maintenance to ensure their normal operation and maintain marking quality. Maintenance tasks include cleaning lenses, calibrating optical paths, replacing parts (e.g., lenses and mirrors), etc. Specific maintenance requirements should follow the equipment manufacturer’s guidance and recommendations.

How Safe is Laser Marking?

Laser marking machines involve laser radiation, so appropriate safety measures must be taken. Laser marking machines are usually equipped with safety devices such as protective covers, safety sensors, and emergency stop buttons. At the same time, operators should strictly follow operating procedures and safety precautions.

What Should I Do if the Laser Marking Machine Cannot Emit Light?

The inability of the laser marking machine to emit light may be caused by the power not being turned on, the laser being damaged, the potentiometer for adjusting the current being in poor contact, etc. It is necessary to check whether there are any problems with the power supply, circuit, optical path, etc., and make corresponding repairs or replacements.

The Position of Laser Marking is Not Accurate?

The inaccurate position of the markings may be caused by the incorrect clamping position of the workpiece, deviation of the position of the laser head aiming at the mark, excessive marking speed, etc.

What Causes Burning During the Marking Process?

Burning during the laser marking process may be caused by excessive adjustment of the laser power, oil stains or oxide layers on the surface of the workpiece, or the distance between the laser beam and the workpiece being too close, etc.

How Accurate is a Laser Marking Machine?

Generally speaking, the accuracy of laser marking machines can reach a very high level, usually in the range of a few microns (μm) to tens of microns. For some high-end industrial laser marking machines, the accuracy can even reach below a few microns, with very high processing accuracy and repeatability.

For example: the repetition accuracy of a certain model of desktop fiber laser marking machine is 0.0025mm, and the marking speed is ≤8000mm/s.

The Marking Accuracy is Not Enough?

Insufficient marking accuracy may be caused by damage to the galvanometer, damage to the reflector, damage to the focusing lens, etc. Damaged parts need to be replaced.

How Deep is Laser Marking?

In daily work, the engraving depth of fiber laser marking machines is between <0.2mm-<1.6mm (depending on different models).

For CO2 laser marking machines, common deep engravings are used for bamboo and wood products. The depth also depends on the marking time and laser power. Generally, it can reach 2-3 mm.

The longer the laser marking machine repeats marking, the deeper the product will be engraved. Generally, the depth can reach about 0.1mm~4mm.

There are also customized deep marking laser machines on the market now, and the depth can reach more than 10mm. For specific situations, you can consult the laser marking machine manufacturer.

What is the Difference Between Laser Engraving Machine and Laser Marking Machine?

Although laser marking machines and laser engraving machines both use laser technology for processing, they are mainly used in different fields and have the following differences:

Application Purpose

Laser marking machines are mainly used to mark, code or engrave on the surface of various materials.

Laser engraving machines are mainly used for deep engraving and cutting of materials. Their processing depth is usually greater than that of laser marking machines, and they can create more three-dimensional patterns or text.

Power Requirements

Generally speaking, laser marking machines require relatively low power and are mainly used for surface marking and engraving.

Laser engraving machines usually require higher-power lasers to achieve cutting and deep engraving of materials.

Scope of Application

In general, laser marking machines are mainly used for surface marking, with high precision and high speed; while laser engraving machines are mainly used for material processing, with multiple processing functions and stronger power requirements. In actual applications, appropriate equipment is selected according to different processing needs.

Do I Need a Computer to Use a Laser Marker?

Normally, laser marking machines need to be connected to a computer for operation and control. Laser marking machines are equipped with corresponding control software. Users need to install the software on the connected computer and use the software to set parameters, import design files and control the operation of the laser marking machine. Therefore, in most cases, you need to configure a separate computer to connect and operate the laser marker.

This computer can be a desktop computer or a laptop. It is best to choose a device with stable performance and compatible operating system. Make sure the connection method with the laser marking machine (such as USB interface, network connection, etc.) is consistent, and follow the operating instructions provided by the laser marking machine manufacturer to correctly connect and operate the device.

However, some laser marking machines, especially mini handheld portable laser marking machines, usually have built-in systems and operating interfaces that can be operated directly without relying on an external computer. This type of equipment is very convenient and practical for simple marking needs or on-site operations.

In addition, some other types of laser marking machines, such as desktop laser marking machines, are equipped with computer systems.

Does Laser Marking Use Ink?

The working principle of the laser marking machine is to achieve the purpose of marking by using a laser beam to remove material or change color on the work surface. After the laser beam is amplified and focused, it can directly illuminate the workpiece locally, causing the surface material to vaporize or undergo a chemical reaction of color change, thereby leaving a permanent mark. In this process, the laser marking machine does not need to use ink to form marks like an inkjet printer.

However, in certain applications, special inks or other marking substances may be used to enhance the marking effect. For example, in some laser marking processes, specific pigments or coatings may be used to change the material’s absorption properties of the laser, resulting in clearer marks. However, this is not a required operation of the laser marking machine itself but is determined based on the specific application requirements.

Therefore, the laser marking machine itself does not require ink. It relies on the interaction between the laser beam and the material to form the mark without the use of ink or other similar substances. However, in certain circumstances, other labeling substances may be used to enhance the marking effect.

Do You Need to Passivate After Laser Marking?

In some cases, passivation may be necessary to enhance the durability of the mark or to prevent the mark from fading.

However, not all laser marking requires passivation. For some materials or applications, laser marking alone can achieve sufficient durability and clarity without the need for additional passivation.

Therefore, whether passivation treatment is required needs to be determined based on the specific materials, marking requirements and application environment.

Does Laser Marking Wear Off?

Laser markings generally do not disappear due to normal wear and tear because laser markings are achieved by permanently changing the properties of the material’s surface. Marking durability depends on factors such as material type, marking depth, and environmental conditions. In extreme cases, such as strong friction or chemical corrosion, markings may be affected.

How Do You Remove Laser Markings?

Removing laser markings is often a challenging task because laser markings are usually achieved by permanently altering the surface of the material. Some methods to try:

Mechanical Grinding

Mechanical means such as grinding tools or grinding wheels are used to reduce the depth of the mark or remove it completely. This method is suitable for shallow surface markings, but it is easy to damage the surface of the object and is less efficient.

Chemical Dissolution

For certain types of laser marking, you can try using chemicals to dissolve the mark. Take care to select the appropriate solvent to avoid damage to the base material.

Laser Removal

A more powerful laser system is used to cover the original mark, but this may have further thermal effects on the material.

Polishing

Polishing the surface can lighten the appearance of the mark, but deep marks cannot be completely removed.

Before trying any method, be sure to understand the characteristics of the material and the specific type of laser marking to avoid irreversible damage to the material. It is best to remove laser markings under the guidance of a professional.

Is Laser Marking Machine Hard to Learn to Use?

Basic level: Master basic operations, such as starting and shutting down equipment, adjusting parameters, selecting appropriate marking patterns, etc. These basic skills are relatively simple and can usually be learned in a short time.

Advanced level: In-depth understanding of laser marking principles, material properties, optimized parameter settings, etc. This requires more practice and experience and may take a longer time to master.

Which Software is Used in Linxuan Laser Marking Machine?

Common laser marking control software includes but is not limited to LaserGRBL, LightBurn, EzCad2/EZCAD, MarkMaster, LaserCAD, etc. The specific software used depends on the brand and model of the laser marking machine. Some laser marking machine manufacturers provide their customized software, which can expand and customize functions according to customers’s needs.

In addition, auxiliary graphic design software: CorelDRAW, AutoCAD, Adobe Illustrator, photoshop, etc..

Linxuan laser marking machines usually use EzCad2 marking software.

What is the Difference Between 20w and 30w Laser Marking Machine?

Processing speed: Since 30W laser marking machines have higher power, they can usually achieve faster processing speeds, thereby improving production efficiency.

Marking depth: 30W laser marking machines may have greater marking depth, and the marking effect on certain materials may be more prominent or easier to achieve.

Cost: Generally speaking, higher-power laser marking machines tend to be more expensive.

Choosing a 20W or 30W laser marking machine depends on factors such as specific application needs, material type, and budget constraints.